STORAGE TANK SYSTEMS

The Nelson Water Systems For Hemodialysis storage tank systems are complete systems specifically engineered to store purified water in the hemodialysis facility.

The Nelson Water Systems For Hemodialysis storage tank systems are complete systems specifically engineered to store purified water in the hemodialysis facility.

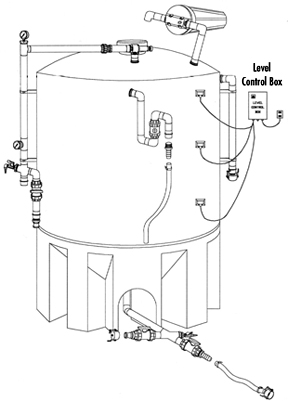

The Nelson Water Systems For Hemodialysis storage tank systems include:

- An enclosed, sealed, conical bottom, high density polyethylene tank (Terracon);

- Tank base;

- Calibrated marking (Gallons)

- Feed water quick disconnect port;

- Air breather filter;

- Return water circuit with sprayer and pressure regulator, thermometer, pressure gauge, sample port;

- Tank bottom outlet circuit with drain and repressurizing pump port;

- Over-flow circuit;

- Tank water level controller.

System Features

Two models to choose from:

| Models |

STS1-125

|

STS1-250

|

| Capacity |

125 gallons

|

250 gallons

|

| Tank Size |

40″ x 56″

|

40″ x 93″

|

| Tank Feed Fitting |

3/4″ Cam-Lock quick disconnect coupler fitting

|

|

| Return Line Fitting |

1” NPT Female Adapter

|

|

| Overflow Hose Fitting |

10 ft 1″ PVC Gray Braided Hose

|

|

| Discharge Fitting |

1″ Slip/Thread Fitting

|

|

| Drain Connection Fitting |

1″ Cam-Lok quick disconnect male fitting, located at side of tank on return line and at the bottom feed line

|

|

| Air Breather Filter |

10″, 0.2µM Absolute Cartridge Filter

|

|

| Gauges |

0-100 psi all stainless steel,

located at top of tank on return line |

|

| Thermometer (Option) |

0 – 250°F (-20 to 120°C), stainless steel,

located at top of tank on return line |

|

| Tank Level Controller |

3 Flowline Switched

|

|

| Electrical |

110 / 220 Vac

|

|

| Size |

40″ x 72″

|

40″ x 105″

|

| Weight |

130 lbs.

|

170 lbs.

|

| Full Tank Weight |

1,050 lbs.

|

2,000 lbs.

|

- Simplistic design with a minimum number of components to minimize bacteria growth sites;

- Complete system ready to install and use;

- Adjustable pressure relief valve on return line;

- Nozzle sprayers that covers 100% of internal surface of tank, located at feed and return line in the tank.

- All stainless steel, non-liquid filled pressure gauge;

- All materials suitable for DI water;

- High / low non-intrusive level controller for RO unit;

- Low level alarm;

- Sample ports at return line;

- Drain connection at side of tank on return line and at the bottom feed line;

- Overflow circuit designed to remove all water on tank side of check valve;

- Sealable cap at top of tank;

- Calibrated markings on tank to show volume of water.

- Custom design is available.

Options

- Air breather wall mount kit

- Bottom connection kit with hose barb

- Bottom connection kit with quick disconnect

- Tank disinfection eductor