Latest Trends and Future Hemodialysis Water Treatment

The Ten Commandments

Today’s hemodialysis water treatment systems are designed based upon the following 10 commandments:

- Utilizing equipment with the latest IT and state of the art technology;

- Recognizing that silt (both organic and inorganic) in the influent water supply is a major issue that needs to be removed at the beginning of the water treatment system;

- Backwashing carbon beds needs to be reduced to a minimum to protect the RO membranes;

- Recognizing that RO membrane fouling is microbiologically based;

- Knowing that scaling of RO membranes is usually a microbiological issue not a boundary scaling issue;

- Utilizing UV and adequate sub-micron filtration before the RO to protect the RO membranes from fouling;

- Understanding that microbiological control in ROs must be designed into the machine by minimizing the use of PVC80 and maximizing the use of stainless steel and heat resistant ultrapure components;

- Utilizing a distribution loop made up of stainless steel and ultrapure components;

- Including on-line 24/7 chlorine monitoring and remote notification systems for both pretreatment and patient loop;

- Achieving sustainability through reducing resource (water and electricity) use by utilizing current scientific knowledge (and not traditional ill-advised practice).

Typical State-of-the-Art Hemodialysis Water Treatment System

1. VFD Booster Pump

- These pumps provide constant pressure.

- When properly engineered into the water treatment system, they are very efficient often paying for themselves in a short period of time through energy savings.

- Further benefits are that they ramp up and ramp down flow smoothly (no hydraulic shocks caused by the turning on or off of a trading pump) and they have a small footprint.

2. Multi-cartridge filter housing

- Multi-cartridge filter housings with 1 µm depth filter cartridges provide effective filtering to protect the media in the carbon tanks.

- Cartridges should only be changed once the delta pressure exceeds 10 psi.

- Cartridges form a cake that filters down to the submicron range.

3. Operation of carbon bed filters

- Carbon bed filters were originally back-washed daily as it was thought this would keep the beds “fresh.”

- However, now it is becoming more recognized that backwashing the media is creating many problems for little benefit. Backwashing the bed causes carbon fines that contribute to the biomass on the RO membranes and cause false positive chlorine breakthrough when the city switches to free chlorine.

- With proper sediment pre-filtration (multi-cartridge filter) carbon tanks should only be backwashed when the delta pressure exceeds 10 psi or once a quarter.

4. Softeners Usage

- Softeners should only used if absolutely necessary.

- When necessary, proportional brining valve heads only use that amount of salt necessary to restore the full capacity of the softener saving both salt and water wastage.

- 50 mg/L should be action level for softener maintenance.

- Bed tanks with anti-scaling media (not magnets) are preferred over softeners. These devices are inexpensive and do not use salt (are not regenerated). They should always be considered if scale protect appears to be a concern.

- Unnecessary use of softeners for hemodialysis water should also considered a crime against nature. Used when not needed wastes both water and salt and pollutes the environment.

Softeners are probably not need in most hemodialysis water treatment systems.

Softeners were traditionally used to protect the RO membrane against scaling. However, as mentioned in greater detail below, now it is known that membrane scaling is mostly an issue of biological growth on the membrane trapping precipitation. In most applications with good anti-microbiological control, an anti-scalant bed conditioner is all that is required to keep the membranes from becoming scaled Anti-scalant beds are gaining recognition in the industrial water market as acceptable alternatives to softeners for many applications.

If a softener is required for an application, then it must have a control head that allows proportional brining. This type of head will only use the amount of brine that is needed to bring the softener capacity back up to 100%. This has the potential for significant salt and water savings if the softener has a single media tank (not twin alternating).

In addition, the newest bed filter control valves have many data logging features that allow the user to be able to know information such as how much water has been softened, how man regenerations have been made over the life of the softener. Other information includes how many gallons of water have been softened since the last regeneration, how many gallons of softening capacity are still available, typical softened water used by each specific day for the last 6 weeks and maximum service flow rate.

When softeners are used, the maintenance action level should be 50 mg/L. Having an action level below that is not necessary and will require maintenance time to investigate and resolve a problem that really either doesn’t exist or is of lesser importance.

5. Multi-cartridge sediment filter / UV Sterilization Unit

RO Membrane Fouling Reduction

Research has been done that shows that membranes in RO machines that carbon filters have an enormous microbiological life on their surface that fouls the membranes. When the carbon tanks were removed, the microbiological life died. The carbon fines from the carbon filter were feeding the abundant life on the membranes.

Much research has been put into understanding and controlling scaling in the water treatment industry particularly with respect to boiler and cooling towers.

- Two types of scaling have been identified: border (wall surface) scaling (plating/depositing) and global nucleation (precipitation) scaling.

- Border scaling occurs when the saturation index point is exceeded for a compound due to temperature. This is why boiler water must not contain carbonates and bicarbonates.

- Global nucleation scaling occurs when the concentration of a compound exceeds its saturation index point and spontaneously produces colloidal sized solids that come out of the solution. This is what happens when de-watering the pretreatment water solution through an RO machine.

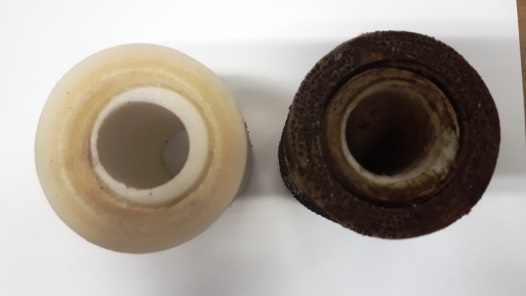

- Membrane scale was originally thought to be a border phenomenon caused by the concentration of the compounds exceeding their saturation point on the surface of the membrane. Research has proved that almost all membrane fouling is caused by microorganism fouling that captures the global scaling precipitate and is the glue for keeping the scale in place.

- These phenomena are the reason that membrane fouling is most prevalent where warm water is used by the RO machine.

Membrane fouling has been significantly reduced by reducing the carbon fines that reach the RO membranes.

- This is done by providing a properly-engineered, multi-cartridge housing with 1-μm depth cartridge filters.

- It is critical that the cartridges in the multi-cartridge housing are only replaced after the data pressure across the housing increases by at least 10 psi.

- The longer the cartridges remain in the housing the better. Research has shown that as the filters start to filter the water, a cake builds up and that the 1-μm nominal initial filtering actually drops to the sub-micro range once the cake is in place.

- The worst thing that can happen is to replace the cartridges before necessary.

- The replace the RO pre-filter cartridges with 0.35-μm pleated cartridges. These filters in the RO cartridge housings will help protect the RO membranes as the multi-cartridge housing cartridge filters start building up the cake.

- An UV sterilization unit is used after the multi-cartridge filter to prevent bacteria from forming colonies on the membranes.

6. State-of-the-Art Reverse Osmosis (RO) Machine

State-of the-Art RO machines typically are designed around PLCs and have graphic displays and rich data logging and mining capabilities. Many have heat disinfection designed into them. All future ROs will most likely have heat disinfection available.

State-of-the-Art RO machines incorporate stainless steel and ultrapure components PVC80 should not be used.

7. Product Water Delivery System (VFD re-pressurizing pump, ultrafilter, Teflon or other high-purity plastic piping)

- VFD pumps provide a constant pressure regardless of the number of hemodialysis machines are in service.

- UF filter

- All patient loops incorporate a UF filter at the beginning of the loop.

- Much progress has been made in UF filters in the area of flow capacity and chemical and heat resistance.

- Current UF filters use 2.5″ x 20″ diameter 0.03 μm – 0.05 μm cartridges filters

- Patient loops

- Heat disinfection of the loop has proved to be very effective in maintaining bacteria-free patient loops.

- Chemical disinfected loops are more susceptible to human error and patient risk if the chemical is not adequately flushed from the system, Teflon tubing has significantly reduced biological growth.

Sustainability Opportunities in Existing Water Treatment Systems

Traditional water treatment systems have abundant opportunities to achieve significant sustainability with regard to natural resource reduction (water, salt, electrical energy). The following are some items that can be considered when planning the process to achieve sustainability.

- Replace non-VFD booster pumps with VFD pumps. Electrical energy savings will give a rapid pay-back period. The pretreatment system function better when the pressure is constant.

- Remove pre-treatment bladder tank when using a VFD pump (VFD pumps come with a small pressure tank, no additional bladder tank is necessary).

- Remove the multimedia filter. A multimedia filter is almost never needed for portable municipal water supply. It doesn’t remove anything and if backwashed daily, wastes 1,000 gpd of water or 365,000 gallons per year.

- Install an adequately sized multi-cartridge filter. It is critical that the carbon tanks be properly protected against the silt and organics in the influent water. Use the cost savings of removing the multimedia filter to pay for multi-cartridge filter.

- Reduce carbon bed backwashing to once a quarter. Backwashing 2 carbon tanks daily wastes 1,000 gpd of water or 36,000 gallons per year. Backwashing 4 carbon tanks daily wastes 720,000 gallons per year.

- Ensure that the polisher carbon beds are always backwashed before the worker carbon beds when backwashed the same day.

- Do a need analysis for the softener. Based on most recent data, most softeners are not needed in hemodialysis water treatment systems. They were originally thought to protect the softener from scale formation. Now, RO scale is recognized as biological fouling that traps the scale precipitate. There is no boundary scaling in membranes. If needed, use a scale-control bed in place of the softener. Removing the softener not only saves significant resources but also reduces the pollution in the drain water.

- Install a pre-RO multi-cartridge sediment filter / UV System before the RO and use 0.35 μm pleated sediment filters in the RO pre-filters. The savings from frequent membrane replacements will pay for the equipment.

Sustainability is part of every Corporate Social Responsibility (CSR) Policy. In order to achieve sustainability for hemodialysis water treatment systems at its facilities, a sustainability development plan needs to be initiated. It includes:

- documenting current resource usage and environmental conditions;

- identifying the sustainability goals;

- identifying the actions that need to be taken to achieve those goals;

- implementing sustainability project;

- monitoring sustainability once achieved.

Nelson Water Systems’ line of Sustainability Sentinels™ were developed for assisting companies identify current resources usage and wastage, document water system performance during the sustainability achievement project, and monitoring sustainability after being achieved.

ADDENDUM A:

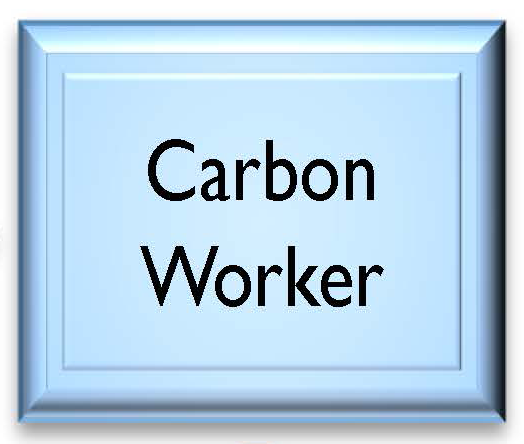

ADDENDUM A: Maximum allowable chemical contaminant levels in water used to prepare dialysate and concentrates from powder at a dialysis facility and to reprocess dialyzers for multiple use a) Contaminant (RD62:2006)